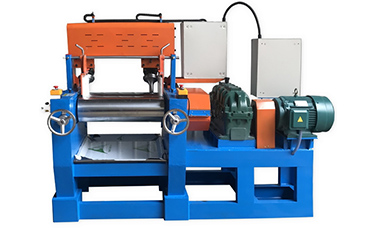

In the realm of rubber processing, precision and quality are paramount, and the Rubber Refiner Mill emerges as a pivotal player. This article delves into the mechanics, applications, and transformative impact of the Rubber Refiner Mill on the rubber industry.A Rubber Refiner Mill, also known as a "refining mill," is a vital component in the rubber processing chain. This machine is designed to break down and refine rubber compounds, achieving improved uniformity and enhancing material properties. The process involves feeding raw rubber or rubber compounds into the mill's rotating rolls, where mechanical forces and heat are applied to achieve the desired outcomes.

The applications of a Rubber Refiner Mill extend across diverse industries. From tire manufacturing and automotive components to industrial belts and consumer goods, rubber products form the backbone of various sectors. The Rubber Refiner Mill ensures the quality, consistency, and durability of these products by refining raw materials and compounds.

Key Advantages and Features

Uniform Dispersion: The mechanical action of the rolls ensures thorough dispersion of additives and uniform blending of rubber compounds.

Particle Size Reduction: The mill's action breaks down larger rubber particles, resulting in finer materials with enhanced properties.

Enhanced Material Properties: The refining process improves material strength, elasticity, and resistance to wear and tear.

Customization: The machine's settings can be adjusted to tailor the refining process based on the desired material characteristics.

Quality Assurance: The Rubber Refiner Mill contributes to achieving consistent quality across rubber products, minimizing defects and variations.

As industries evolve, so does the potential of the Rubber Refiner Mill. Integration with automation and digital control systems can enhance precision, reduce manual intervention, and optimize refining parameters. Real-time monitoring and data analysis can fine-tune the refining process, resulting in higher efficiency and improved material performance. Additionally, exploring sustainable rubber formulations and incorporating recycling practices align with the growing emphasis on eco-friendly manufacturing.The Rubber Refiner Mill showcases the synergy of engineering and material science in the pursuit of excellence. Its ability to refine raw rubber and compounds into high-quality materials is a testament to the advancements in manufacturing. As industries progress, the Rubber Refiner Mill remains at the forefront of rubber processing, ensuring that the rubber products we rely on daily are of the highest caliber.