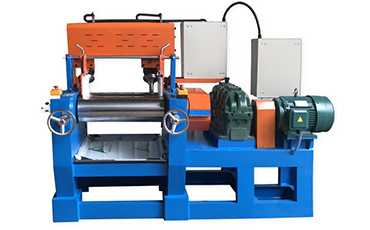

In the realm of manufacturing, innovation drives progress, and one such innovation that has revolutionized the rubber industry is the Rubber Forming Machine. This dynamic apparatus plays a pivotal role in shaping raw rubber into a myriad of useful products. This article delves into the intricacies of the Rubber Forming Machine, its applications, and its significance in shaping the future of rubber manufacturing.At its core, the Rubber Forming Machine is a mechanical marvel designed to shape raw rubber materials into various forms, ranging from sheets and mats to intricate components. This process involves subjecting the rubber to heat and pressure while employing different techniques such as compression molding, injection molding, and transfer molding. The result is a wide array of rubber products that serve diverse industries.

Applications Across Industries

The versatility of the Rubber Forming Machine is evident in its widespread applications. It caters to industries such as automotive, aerospace, electronics, healthcare, and consumer goods. Tires, gaskets, seals, and various rubber components owe their existence to the precision and efficiency of this machine. Its ability to create intricate designs with consistent quality makes it indispensable in modern manufacturing.

Key Factors for Optimal Performance

Material Preparation: The quality of the final product depends on the quality of the raw material. Proper preparation, including material selection, blending, and preheating, ensures desired characteristics in the finished product.

Mold Design: The design of the mold used in the forming process significantly impacts the outcome. Molds must be tailored to the product's specifications, ensuring accurate dimensions and surface finishes.

Temperature and Pressure: Precise control of temperature and pressure during the forming process is crucial. These factors influence material flow, curing, and final product properties.

Cooling and Ejection: Efficient cooling ensures that the formed rubber retains its shape. Proper ejection mechanisms prevent damage to the product during removal from the mold.

Automation and Efficiency: Advancements in automation technology have led to more efficient rubber forming processes. Automated systems reduce human error and enhance production rates.

Paving the Way Forward

As industries continue to innovate, the Rubber Forming Machine evolves alongside them. The integration of digital technologies, real-time monitoring, and data-driven insights promises to elevate the efficiency and accuracy of rubber forming. 3D printing and advanced materials are also beginning to intersect with rubber manufacturing, opening new avenues for creativity and performance.

In conclusion, the Rubber Forming Machine stands as a testament to human ingenuity and the pursuit of excellence in manufacturing. Its ability to transform raw rubber into a multitude of useful products showcases the convergence of engineering and material science. As technology propels industries forward, the Rubber Forming Machine's role in shaping the future of manufacturing remains unwavering.

Previous: Exploring the Two-Roller Mill